Powder coated lighting fixtures with produced in the technology used by ATM Lighting ensure anti-corrosion resistance for many years. This is very important in the case of LED luminaires, whose lifetime is tens of thousands of hours and is constantly increasing with the development of technology. Continous operation 24/7 it is a period of over 8 years! In our opinion, one of the weakest element of luminaires with a metal body is the paint coating that protects the housing against external factors such as dirt, aggressive environment or mechanical damage. In addition, the dust settling on the luminaires over time makes it difficult to dissipate heat outside the luminaire. High temperature adversely affects the life of electronic components installed in the luminaire. In extreme cases, a layer of dust on the luminaire may ignite. The duty of the luminaires user is their regular maintenance, including cleaning, which generates additional costs and may cause breaks in the work of the plant. For this reason, we decided to delve into the world of science and solve this problem at the root!

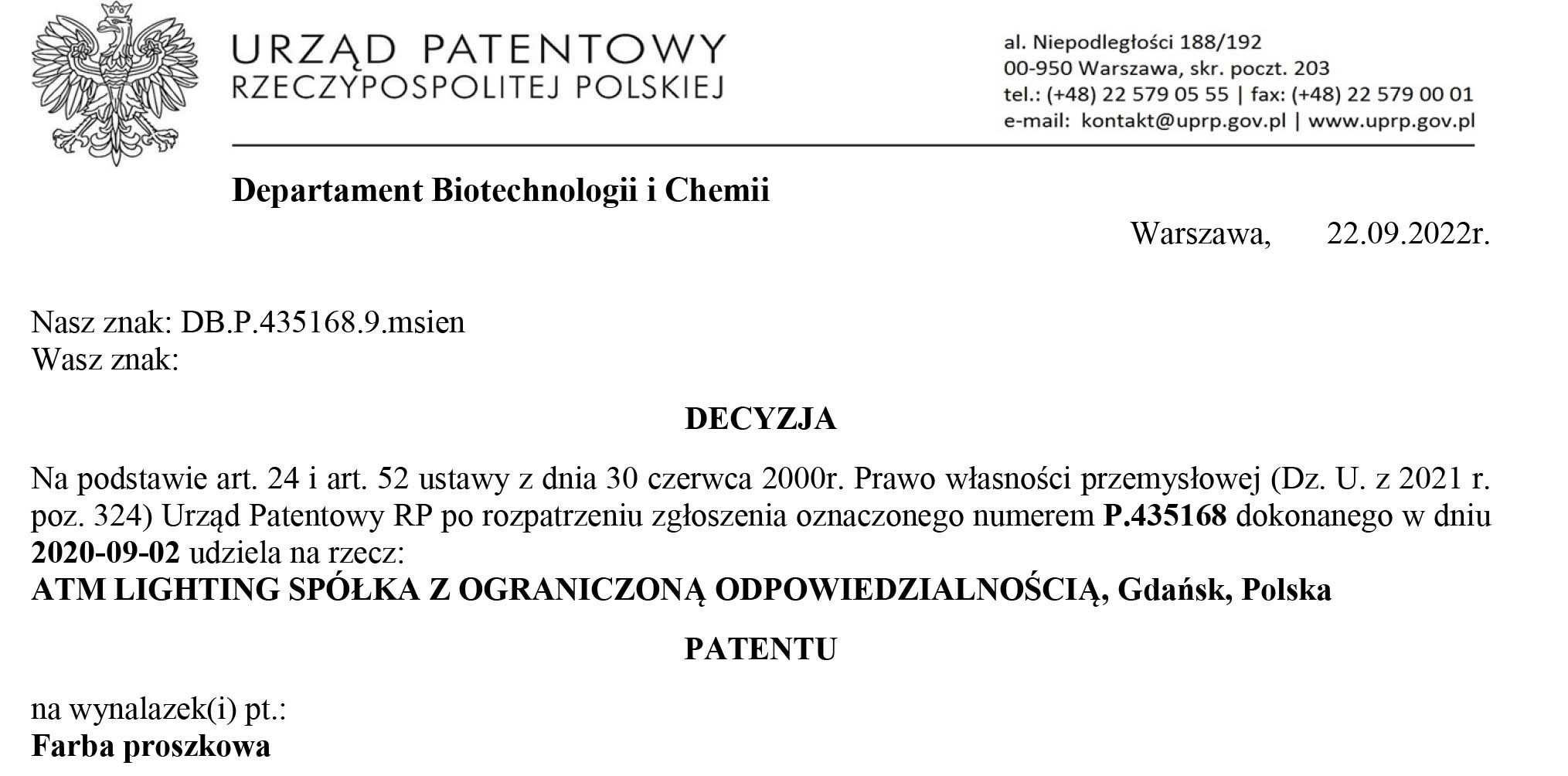

Together with the Rzeszów University of Technology Ignacy Łukasiewicz, we carried out research and development works consisting in the modification of powder paints in the direction of giving them antistatic properties, increasing the hydrophobicity of coatings and scratch resistance. The recipe was submitted to the Patent Office of the Republic of Poland and received a patent number P.435168.

Surface preparation before painting

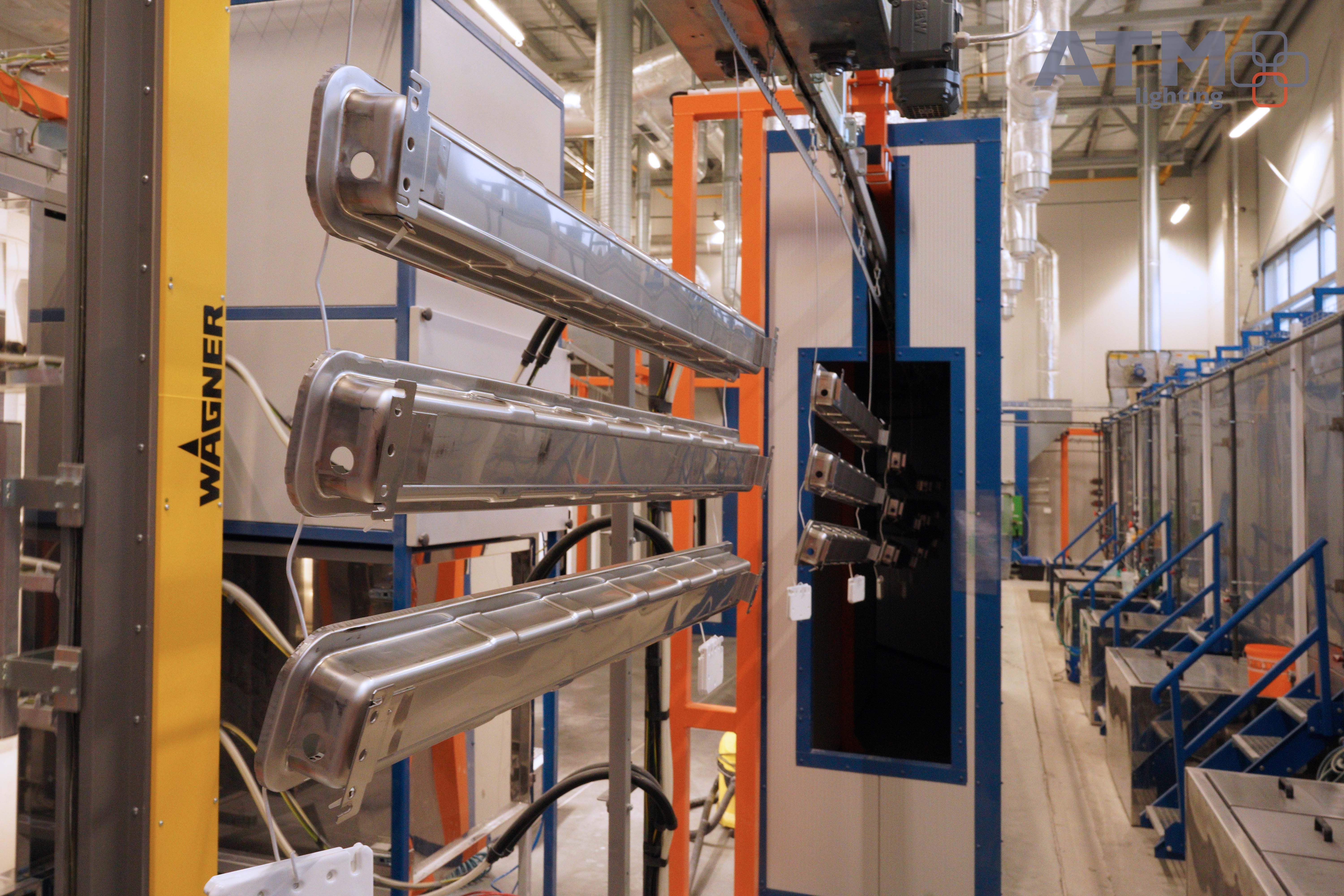

When we talk about corrosion protection of the luminaire housing, we must pay attention to surface preparation before painting. In our new paint shop, designed and built by Budrem Sp. z o. o. A six-zone pressure washer is "responsible" for surface preparation. In cooperation with Henkel, we opted for a new technology based on zirconium conversion, which has better anti-corrosion properties than iron or zinc phosphating, is low-temperature (energy saving) and environmentally neutral. It does not contain phosphates, heavy metals and other hazardous substances. After performing 480-hour tests in the salt chamber, we received very good results - no paint chips were observed, even after impact tests.

washed and dried housing prepared for painting.

test report from salt chamber.

Why do customers need luminaires painted with modified powder paint?

Thanks to the use of the most modern solutions, our luminaires can enjoy increased resistance to external factors. The paint developed by us makes the luminaire stay clean for a longer time. In this way, we prevent the formation of layers of sediment, extending the life of the luminaire. As a result, you can extend the time between periodic reviews and thus save money not only on maintenance and cleaning of the luminaires, but also avoid losses caused by stopping production.

Thanks to the system of six automatic applicators from WAGNER-SERVICE Sp. z o. o. Sp. K., developed and patented by our company, the paint is distributed perfectly evenly. An additional manual applicator allows you to cover even the smallest details of the luminaire with powder. After the powder application process, the element goes to the oven, where the polymerization process takes place. This allows to obtain a very durable coating on the surface of the element.

To sum up...

Nowadays, it is easy to fall for cheap products that look quite solid from the outside. However, it should be remembered that there are many factors behind the durability of a luminaire. Importantly, they interact with each other. Even the most durable components will not cope with long-term overheating or under the influence of aggressive environmental factors. At ATM Lighting we are aware of this and we protect our products at every stage of their production. We choose the most resistant steel grades for the enclosures, which we then precisely cut and assemble into the enclosure. At the next stage, we protect the steel with a modern method (zirconia conversion), and then powder coat it in a fully automated and carefully calibrated powder paint shop. We use a special powder paint developed by us, which, in addition to increased durability, also gives the coating hydrophobic and antistatic properties. This affects the comfort of use, extended time between periodic inspections and better conditions for heat exchange between the interior of the luminaire and the environment. As a result, the solutions implemented by us protect the components in the luminaire in a direct way (increased durability of the housing) and indirectly (better working conditions). And all this so that our luminaires serve as long as possible and are second to none.